written by: Faiz Akbar

Technology development in an industry is often making an effect on several aspect in an industry. One of the aspect is the improvement of technology is whether the output can be increased or decreased. Hard to say that the implementation of technology or the improvement often could take a costly risk if to be applied in the real system before it get checked. Wrong move in implementation can make an industry falling down and risking their employees wellbeing. This is why some small to medium industry does not have the motivation to even try the new technology or new way of producing their products.

One of method to understand the behavior of system is by modelling the system with simulation. This method became very useful when used for experimenting on a system without risking the real system to fail because we can do the experiment on virtual system that resemble the real one.This method is also considered low cost because the time and risk it requires.

That condition is the reason of using simulation method in small to medium industry became one of a choice to be considered. Simulation method can be done by mathematical model or using simulation software. Mathematical model can be useful when the solution is prefer to be exact and precise without taking time and cost necessary to do the experiment in real system.

Start this business on late 1980 in purbayan, kotagede, Yogyakarta. SR Silver was founded by Mr. Slamet in motivation to make a better living for him and his associate. Focusing his skill in the art crafting since graduated from elementary school, 3 years later he open the RS silver by himself and begin to craft brass, silver, and copher base handcrafting. Mostly of the product is accessories like ring, earrings, medal, but there is also miniature statue and more special variant of his making.

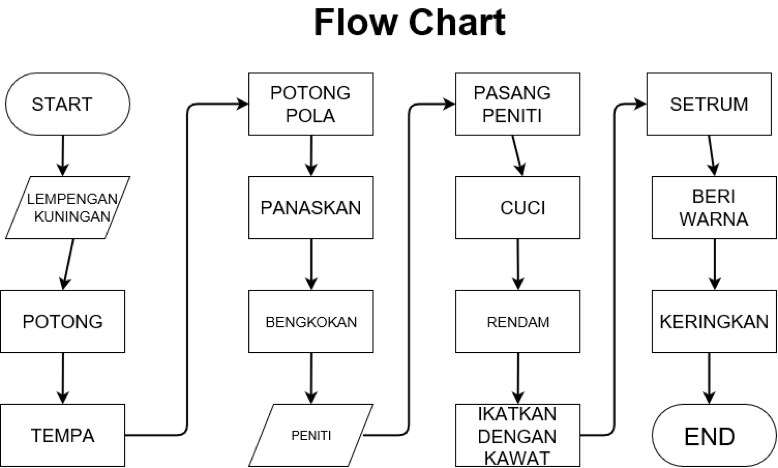

In this Simulation, we’re going to fing a way to increase the output production of the most profitable product that RS silver able to produce. The product is graduation medal that is used when graduation of college student in some national universities. Raw material that is used is a sheet of brass in size 36 x 120 cm2. This wide sheet later cut into several smaller sheet in size 8 x 9 cm2. Then the small sheet is punched to get emboss pattern of the university logo. The tool used for this process is a hammer and soft metallic waste material of aluminium. The next process is to cut the excess material outside the outline of logo. Then the half finish medal get a bit of heat treatment by fire torch until become red hot colored then quickly cool it down. Sheet that have been heat treated is easier to bend to the elipsical round shape. Make the shape using a hammer dan hit it slowly until it reach the necessary hardness. After that process pin can be attached to the medals. The pin is attached by welding it tu the back surface of the medal. After it dry the medal must be wash in a special solution to bring the natural color and surface. And then the medal is get into the eletroplatting process to bond the gold liquid into the medal surface area. The last step is to let dry the medal with shred of wood.

Figure 1. Flowchart Medal Production Process

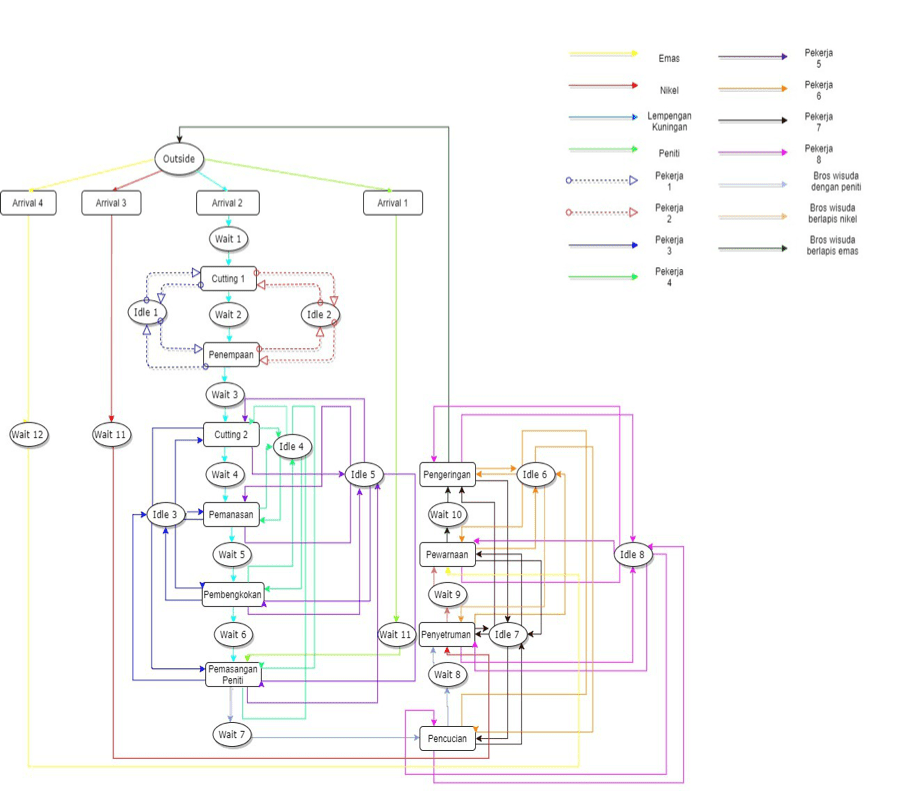

Figure 2. Activity Cycle Diagram

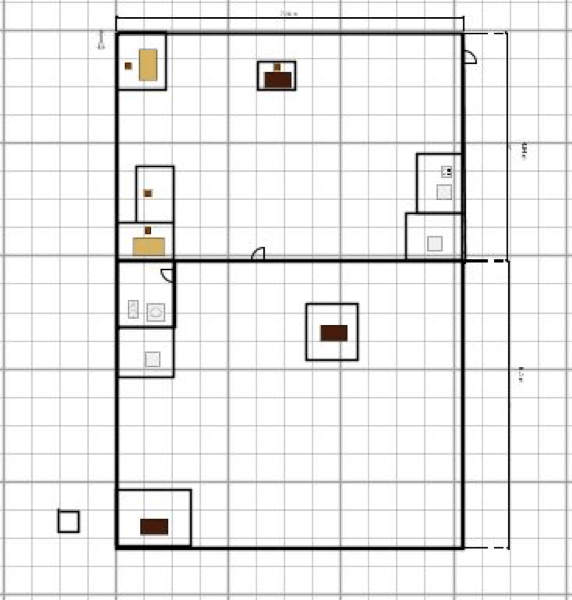

Figure 3. Production Layout 3D and 2D

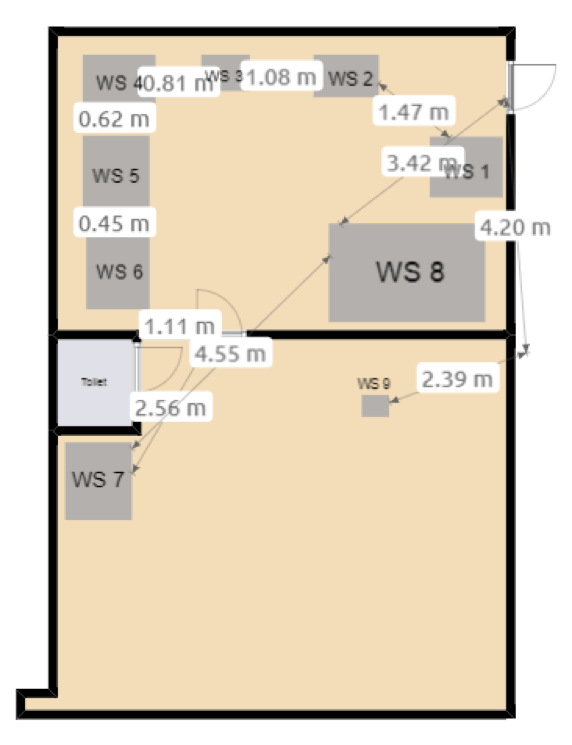

The Simulation is used to implement some improvement to increase the output production up to twice their production before. This improvement is done by implementing 9 points of improvement and proved to be effective to increase the production output.(1)Increase Worker transport Capacity by giving a basket to bring more WIP.(2)adddispatcherdan transporterteam. (3)Change Layout Design. (4)Changing intomultiprocessor in activity 2,3 and 4,5,6. (5)add batch before entering workstation.(6)ChangeWorkstation Capacity by giving more bucket.(7) dismissed overnight work to reduce the change of unhealthy workers.(8) reduce rest time with more strict rules.

According to work time data of each activities studied, improvement have been tested on virtual system simulation on FlexSim Software at success in reaching twice the output production with the same time frame that is given.

Figure 4. NewProduction Layout 2D